Workshop Documents:

The finalized workshop documentation:

Sustainable Manufacturing Roadmap - Executive Summary with 12 Key Imperatives

Sustainable Manufacturing - A Business Perspective: Summary Document (03/13/2015)

Sustainable Manufacturing - A Business Perspective: A Technology Roadmap Draft (02/25/2015)

Sustainable Manufacturing - A Business Perspective: Pre-Read Materials (11/10/2014)

The content that was developed during the workshop:

Solutions Ballot sorted with team assignments

Project scoring and ranking ranked

Products solutions presentation

Products projects presentation

Processes solutions presentation

Processes projects presentation

Systems solutions presentation

UPDATE: Sustainable Manufacturing Roadmapping Workshop Successfully Held Nov. 12-14, 2014

Posted - November 16, 2014

ISM recently organized and hosted a two-day Sustainable Manufacturing Roadmapping Workshop in conjunction with the project partner, Integrated Manufacturing Technology Initiative (IMTI). This workshop was held at the historic Spindletop Hall of the University of Kentucky on November 12-14, 2014. The specific goals of this workshop are to:

- add to the collective knowledge and understanding regarding sustainable manufacturing,

- define an industry-led vision for the PRISM consortium,

- provide the foundation for a sustainable manufacturing technology roadmap to address business and technical issues,

- introduce and mature a business-driven approach for prioritizing sustainability investments, and

- begin the process of establishing a collaborative research agenda.

The workshop focused on products, processes and systems. A total of 44 participants from industry, academia, government organizations, including DoD, attended the workshop and were actively engaged in lively discussion. A comprehensive report is currently being prepared by IMTI, and will be available to all participants by mid-December 2014.

Two additional segment-specific sustainable manufacturing workshops will be organized and hosted by the National Center for Manufacturing Sciences (Ann Arbor, MI).

Sustainable Manufacturing - A Business Perspective Workshop

Value Statement: By addressing sustainability as an integral component of the total product development, production, and lifecyle system and by taking a bottom-line business-driven approach to defining needs and establishing priorities, a crosscutting research agenda will be established and supported.

The Institute for Sustainable Manufacturing (ISM) at the University of Kentucky seeks your help in defining the critical research needs for business-focused sustainable manufacturing. A workshop will be held at Spindletop Hall in Lexington, KY on November 12-14 for the purpose of collecting information to build a technology roadmap. This activity is supported by the National Institute of Standards and Technology (NIST) Advanced Manufacturing Technology Consortia (AMTech) program. The ultimate goal is to develop a dynamic alliance of industry, academia, and government that will define needs and opportunities, establish the business value and prioritize the needs, and create a dynamic, collaborative research and development consortium that will deliver monetized and measureable value to U.S. industry. That alliance is called the Partnership for Research and Innovation in Sustainable Manufacturing (PRISM).

Call to the Workshop

Sustainable manufacturing has been a topic of discussion for many years. There have been multiple studies, workshops, and roadmaps on the subject, and good work has been done. However, in the main, sustainability issues have struggled to find their place with affordability and producibility as key drivers in the requirements-to-design migration for advanced manufacturing. Sustainability related issues are often addressed on a case-by-case basis, many times in response to imposed requirements. Too often, life-cycle analysis is viewed as a regulatory obligation more than an optimization opportunity.

The founding partners of PRISM, General Electric Aviation, Toyota, Lexmark, and the University of Kentucky, postulate that there is a better way. By addressing sustainability as an integral component of the total advanced manufacturing system and by taking a bottom-line business-driven approach to defining needs and establishing priorities, a crosscutting research agenda can be established and supported. This mindset is the foundation for the work of PRISM and will be the guiding force in the conduct of the November workshop and the preparation of the technology roadmaps.

Structure

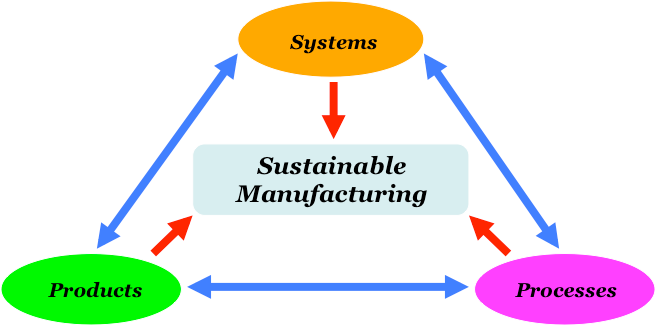

As is illustrated in Figure 1, the workshop will address sustainable manufacturing from three perspectives: products, processes, and systems.

The integration of these perspectives will not be overlooked. To assure a common understanding, the following illumination is provided:

Sustainable Products

Efficient development of innovative products is a flagship challenge for advanced manufacturing enterprises. The ability to comprehensively define product requirements, and to optimize the product attributes with minimal physical testing, leads to improved productivity, affordability, profitability, and sustainability. This emerging methodology is a departure from the mindset that new products development is mostly an incremental improvement of existing products. Product development can be a dynamic learning process that supports and enriches every phase of the product lifecycle.

Envision an ability to define possible responses to product requirements and have immediate access to the sustainability and regulatory implications of the responses. Envision shared materials databases that support expert advisors that accurately define performance and cost and provide environmental impact and energy efficiency assessment. Envision life-cycle analysis systems that draw on a rich knowledge base and accurately assess the sustainability cost factors of various product scenarios over a product's lifecycle. The Products group will pursue a vision and project slate for the inclusion of sustainability in the realization of this requirements-based product development environment.

Sustainable Processes

Manufacturing processes can be defined as the operations required to transform, by mechanical or chemical means, a material or product to a state that is closer to the finished product. Some products are manufactured in one or two transformations. Others require many operations and transformations. The goal in sustainability is to assure that each of these transformations is efficient, cost-effective and environmentally responsible. The sum goal is to optimize, not the individual operations, but the integrated processes that comprise the complete transformation system.

The challenge is threefold:

1) to identify important crosscutting opportunities for dramatic improvement in individual processes,

2) to assure that sustainable processes take their place in the sustainability equation, and,

3) to create an integrated optimization environment wherein process design, plant design, and plant operations are all integrated to create a totally optimized processing environment.

Envision systems that access product and materials requirements and specifications and allow the operator to define process alternatives and receive an accurate evaluation of the sustainability index of the various selections. Envision extending that assessment to produce optimized integrated and optimized process plans with sustainability as a key factor. Envision the ability to define materials and processes and receive an accurate assessment of the cost either positive or negative for available sustainability choices. Envision expert toolsets that call upon captured and learned knowledge to evaluate emerging technologies and capabilities and assure the best process selections. The Processes team will build their own vision, which may include some of these capabilities.

Sustainable Systems

While it is legitimate and expedient to address product and process details independently, it must not be forgotten that transformational improvements in design and manufacturing come from systemic changes. To achieve the goals of productivity, affordability, profitability, and sustainability, products, processes, and resources must be addressed as an integrated system, and the optimization must apply across the design, production and operations environment. The realization of a complete and integrated view of optimized systems for design and manufacturing dictates that we rethink our traditional siloed approach. New toolsets must be developed that support the evaluation of alternatives and the quantitative selection of the best solutions for products, processes, and resources.

Envision a desktop on which combinations of materials, product design features, process options, and sustainability impacts are objectively and accurately evaluated in real time. Envision an optimization environment in which these factors are optimized for best total value. Envision the ability to analyze the business case and return on investment for the various alternatives. This visionary state defines a grand challenge for advanced manufacturing systems. The burden of delivering this visionary system is not placed on the sustainability community. However, it is the responsibility of the sustainability community to define strategies to assure that sustainability takes its place along with affordability and producibility in the total optimization equation. The workshop will explore the systems approach and the integration of sustainability in the advanced manufacturing system.

Goals:

The ultimate goal of PRISM is to build an alliance a consortium that will establish a common vision for sustainable manufacturing, define the key needs that must be addressed to realize the vision, and emplace a project slate that will deliver value to all stakeholders. This workshop is an early step in that process. The specific goals of this workshop are:

To add to the collective knowledge and understanding regarding sustainable manufacturing

- To define an industry-led vision for the PRISM consortium

- To provide the foundation for a sustainable manufacturing technology roadmap to address business and technical issues

- To introduce and mature a business-driven approach for prioritizing sustainability investments

- To begin the process of establishing a collaborative research agenda

Conduct of the Workshop

The workshop will consist of a combination of large and small group sessions. We will divide ourselves into small groups via the three perspectives: products, processes, and systems. A professional facilitator will lead the group through an exploration process. We will define the starting point, the vision state, and the pathway to realization of the vision. We will then prioritize the solution opportunities and begin the process of building a project slate.

1) Needs: In this session, we will conduct a needs assessment. Deficiencies, barriers, challenges, and opportunities will be tabulated. We will also capture emerging best practices.

2) Vision: If we could have whatever we desire regarding sustainable manufacturing, what would that state be? What are the attributes of the state that we seek to create? By capturing the attributes of the vision state, we will set the target for PRISM.

3) Solutions:With emphasis on technology R&D and the business case for developing and deploying those technologies, what actions - business processes changes, cultural responses, or technology development - are required to respond to the needs and move toward the vision state?

4) Prioritization and Project Definition:The solutions that are defined in the small groups will be reviewed and discussed by the large group, and a prioritization process will be used to select the most compelling themes. These compelling themes will become the topics for continuing effort, after the workshop, to define and build project slates to deliver value for PRISM and the nation.

Who should attend?

Leaders from across the manufacturing spectrum are invited to attend. We seek the voice of industry, so representatives from manufacturing enterprises of all sizes are essential for a successful workshop and roadmap. We seek to build a roadmap that will address the needs across sectors. We encourage participation from automotive, aerospace, consumer products, electronics, the continuous process industry, and others. We seek the knowledgeable voice of strategic thinking R&D leaders. Hence, we encourage researchers from academia, national labs, and other research organizations to participate. In return, participants will be enriched by the discovery process, will have their needs brought forward for consideration in the roadmap and subsequent projects, and will engage early in the living process of defining and addressing key needs that will be PRISM.

The Path Forward

Registrants for the workshop will receive a pre-reading package approximately 2 weeks before the workshop. The purpose of this package is to assure a common foundation of understanding for the participants as the workshop begins. This common understanding will expedite the discovery process.

This workshop is only the beginning of the PRISM journey. Very soon after the workshop, the knowledge that is captured will be published in a technology roadmap. The key findings will be defined. The roadmap and the key topics will provide foundational materials for a series of dedicated, sector-based workshops (aerospace, automotive, etc.) that will explore responses to the key topics and specific sector needs. These workshops will take place beginning early in 2015. This exploration process will produce an R&D project slate that PRISM will adopt and execute, with recommendations to NIST and other funding agencies.