ISM in collaboration with the Army Research Laboratory (ARL) is engaged in a multi-year research program focused on rapidly advancing the state-of-the-art in additive manufacturing (AM). Novel fusion-based and solid-state AM technologies are being employed to manufacture next generation materials systems for DoD and Industrial applications. The following AM technologies are currently being established in this program:

AM Technologies

Ideal for high resolution AM of complex geometric components and features not possible with any other manufacturing technology

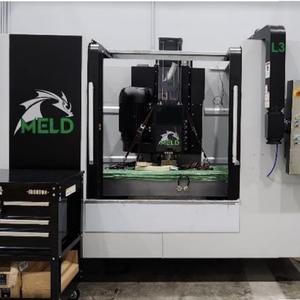

Additive Friction Stir Deposition (AFSD) - MELD L3

Unlimited scalability and high deposition rates make this technology ideal for rapid solid-state AM of large-area components

Additive Friction Stir Deposition (AFSD) - Bond GL7

Unlimited scalability and high deposition rates make this technology ideal for rapid solid-state AM of large-area components

Cold Spray Additive Manufacturing (CSAM)

Ideal for large rapid AM of conformal geometries and point-of-need applications

Wire Arc Additive Manufacturing (WAAM)

- High process scalability and deposition rates ideal for rapid fusion-based AM of large-area components

- Multi-robot solution offering simultaneous Wire-Arc/ Hybrid DED along with subtractive machining in one large-scale manufacturing cell

- Highly unique “Powder-to-Part” multi-robot hybrid DED manufacturing cell

Meltio Laser Directed Metal Deposition (LMD)

- Multi-robot solution offering simultaneous Wire-Arc/ Hybrid DED along with subtractive machining in one large-scale manufacturing cell

- Highly unique “Powder-to-Part” multi-robot hybrid DED manufacturing cell

A new, state-of-the-art AM research laboratory is currently being developed within ISM that will house several unique AM systems, including those above. The first will be operational in early summer (the remaining systems are anticipated in the fall) and will include a MELD L3 AFSD system, as well as a CSAM system from VRC Metal Systems. Both are solid-state AM technologies, where layer building mechanisms are based on plastic deformation at elevated temperatures, rather than melting and solidification. This leads to highly stable and consistent manufacturing processes, in which unwanted phase transformations and tensile residual stresses can be avoided, and site-specific material properties can be engineered in unique configurations.

For AFSD, these characteristics will be harnessed to develop novel nanostructured and functionally graded materials. For CSAM, our initial research focus is on developing mathematical models which describe the influence of velocity gradients within the supersonic flow field on the resulting material properties and defect generation.

ISM researchers are utilizing these new technologies to push the boundaries of innovation and help establish UK as a world leader in advanced AM.